PROPOSED RESIDENTIAL HOME @

THIRUNINRAVUR, THIRUVALLUR.

Types of Stone

StandardSeveral types of stone are readily available today. Each type has its own unique quality and suitability. Some of the most popular varieties are:

Granite:

Granite contains three main minerals – quartz, alkali feldspar, and plagioclase feldspar. These minerals make granite white, pink, or light grey. Granite also contains small amounts of dark brown, dark-green, or black minerals, such as hornblende and biotite mica.

Granite is one of the oldest, most durable and most respected of building materials. It is typically the hardest of the dimensional stones and withstands the elements very well. It is best for kitchen countertops because it is scratch, stain and heat resistant. It is also suitable for flooring or paving, wall cladding and all other types of countertops. Granite is suitable for either exterior or interior applications.

Slate:

Slate consists mainly of grains of mica and quartz, plus small amounts of chlorite, hematite, and other minerals. Most slate is grey to black in colour, but the rock may be red or purple, depending on its mineral content.

Slate is one of the world’s oldest natural products. The building industry uses slate for roofing and flagstone because the rock is weatherproof and long lasting. It is also used to trim the fronts and lobbies of buildings. Slates are typically used for flooring, roofing, and countertops. Most slates are suitable for interior and exterior applications.

Limestone:

Limestone is a type of rock made up mostly of calcite, a mineral form of calcium carbonate. Most limestone is grey, but all colours of limestone from white to black have been found.

Limestone makes an excellent building stone because it can be carved easily. It is typically used for flooring, wall cladding, vanity tops, furniture or ornate stonework.

Sandstone:

Sandstone commonly consists of sand sized grains of quartz, feldspar, and other minerals. It may also include organic matter or rock fragments. The minerals that cement the grains include quartz, pyrite, or calcite. The colour of sandstone ranges from cream, grey, red, brown to green, depending on the cements and impurities in the sand. Brownstone, reddish-brown sandstone, was once widely used to build houses.

It is typically used as flooring or paving materials. Most sandstones are suitable for both interior and exterior applications.

Marble:

Marble consists chiefly of calcite or dolomite, or a combination of these carbonate minerals. Marbles are basically metamorphosed limestones. It has similar characteristics to limestones and is typically used on the same applications. However, marbles are almost always more aesthetically valuable and available in much wider ranges of colours.

Marble has long been highly valued for its beauty, strength, and resistance to fire and erosion. It is a rock widely used in buildings, monuments, and sculptures. Large blocks of coloured marble are used for columns, floors, and other parts of buildings. It is suitable for wall-cladding, roofing, flooring and all other interior and exterior applications.

Quartz:

Quartzite is a stone composed of grains of quartz cemented together by silica. It is a firm and compact stone with a body harder than marble. Its color is a blend of light and dark greys and silver with flecks of quartz lending a sparkle.

Quartzite is a durable stone which is primarily used for interior and exterior floors; however, it may be used for wall-cladding, roofing and other types of interior and exterior applications as well.

Travertine:

Travertine is limestone that has been formed over a long period of time. The product is porous with many visible holes. It is available in colours ranging from ivory to golden brown. The holes and cavities may be filled with matching portland cement, coloured epoxy, or polyester resins or left unfilled for a more rustic appearance.

It is normally used for flooring, wall cladding, vanity tops, fireplace surrounds and furniture.

Theory of Earthquake

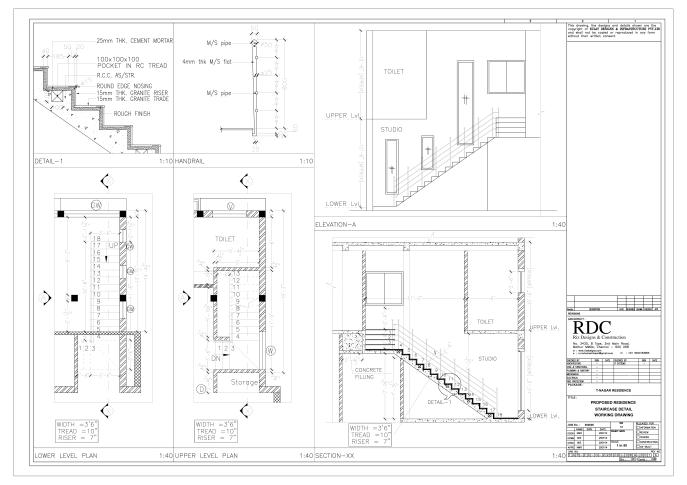

StandardSTAIRCASE DETAIL

Image

PROPOSED RESIDENCE AT T-NAGAR

STAIRCASE DETAIL

WORKING DRAWING

AN INDIVIDUAL VILLA (UPDATED VIEW)

StandardAn Individual Villa

StandardTower of Pisa

Standard-

Address: Piazza del Duomo, 56126 Pisa, Italy

-

Height: 56 m

-

Opened: 1372

-

Function: Bell tower

-

Architectural style: Romanesque architecture

Defects of Bricks

StandardDefects of Bricks:

•Over-burning – Burnt beyond complete vitrification

•Under-burning – Burnt less not to cause complete vitrification

•Bloating – Spongy swollen mass over the surface due to excess carbonaceous matter and sulphur

•Black Core – Due to bituminous matter or carbon

•Efflorescence – Grey of white crystallization of alkalis on the surface, due to water absorption

•Chuffs – Deformation due to rainwater falling or hot bricks

•Checks or Cracks – Due to lumps of lime getting in contact with water

•Spots – Dark sulphur spots due to iron sulphides

•Blisters – Broken blisters due to air entrapped during molding

•Laminations – Thin lamina produced due to air entrapped in voids of clay

Types of Brick Bonds

StandardTypes of Brick Bonds:

In brick masonry, there are many techniques to stack bricks. These different arrangements are known as bricks bonds. Each bond has its own characteristics. Following are the commonly used bricks bonds.

1.Stretcher Bond

2.English Bond

3.Flemish Bond

4.Common/American/English Garden Wall Bond

5.Flemish Garden Wall Bond

6.Herringbone Bond

1. Stretcher Bond

•Easiest bond to lay & it minimizes the amount of cutting required.

•Originally used for single brick walls.

•It is used for cavity walls as less cutting is required.

•Walls are half brick wide.

•No two adjacent vertical joints should be in line.

2. English Bond

•Alternative courses of headers and stretchers.

•One header placed centrally above each stretcher.

•This is a very strong bond when the wall is 1 brick thick (or more thicker).

•One of the strongest brickwork patterns.

3. Flemish Bond

•Alternate bricks are placed as header and stretcher in every course.

•Each header is placed centrally between the stretcher immediately above and below. This is not as strong as the English bond at 1 brick thick .

•It can be successfully applied in cavity wall.

4. Common/American/English Garden Wall Bond

•A pattern made like Stretcher bond but with a row of headers replacing every nth course (n is usually odd).

5. Flemish Garden Wall Bond

•In this variant of Flemish bond, one header is placed at every third stretcher.

6. Herringbone Bond

•It is a purely decorative bond. It is used in floor and wall panels.

TYPES OF PORTLAND CEMENT

Standard

TYPES OF PORTLAND CEMENT

- Ordinary Portland Cement (Type I)

- Modified Portland Cement

- Rapid Hardening or High Early Strength Portland Cement (Type III)

- Quick Setting Cement

- Low Heat Portland Cement (Type IV)

- Sulphate Resistant Portland Cement (Type V)

- Water Repellent Portland Cement

- Water Proof Portland Cement

- High Alumina Cement

- Portland Slag Cement

- Air Entraining Portland Cement (Type I-A, II-A, III-A)

- Pozzolana Portland Cement

It is used in general construction works. All other varieties of Cement are derived from this Cement.

- White Cement

- OPC with pure white color produced with white chalk or clay free from iron oxide.

- Instead of coal, oil fuel is used for burning.

- Much more costlier than OPC.

- Colored Cement

- Suitable pigments used to impart desired color.

- Pigments used should be chemically inert and durable under light, sun or weather.

- This cement on setting develops less heat of generation than OPC.

- It is best suited in hot climate for civil works construction.

- Gains strength faster than OPC. In 3 days develops 7 days strength of OPC with same water cement ratio.

- After 24 hours – not less than 160 kg/cm2

- After 72 hours – not less than 275 kg/cm2

- Initial and final setting times are same as OPC.

- Contains more tri-calcium silicate (C3S) and finely ground.

- Emits more heat during setting, therefore unsuitable for mass concreting.

- Lighter and costlier than OPC. Short curing period makes it economical.

- Used for structures where immediate loading is required e.g. repair works.

- Sets faster than OPC.

- Initial setting time is 5 minutes.

- Final setting time is 30 minutes.

- Used for concreting underwater and in running water.

- Mixing and placing has to be faster to avoid initial setting prior to laying.

- Low percentage (5%) of tri-calcium aluminates (C3A) and silicate (C3S) and high (46%) of di-calcium silicate (C2S) to keep heat generation low.

- It has low lime content and less compressive strength.

- Initial and final setting times nearly same as OPC.

- Very slow rate of developing strength.

- Not suitable for ordinary structures.

- Shuttering required for long duration so cost will increase.

- Prolonged curing is required.

- Structure utilization will be delayed.

- Percentage of tri-calcium Aluminate (C3A) is kept below 5% resulting in increase in resisting power against sulphates.

- Heat developed is almost same as Low Heat Cement.

- Theoretically ideal cement. Costly manufacturing because of stringent composition requirements.

- Used for structures likely to be damaged by severe alkaline conditions like bridges, culverts, canal lining, siphons, etc.

- It contains a small percentage of water-proofing material with the cement and is manufactured under the name “Aqua-crete”.

- The cement is prepared with ordinary or rapid hardening cement and white cement.

- It is used in to check moisture penetration in basements etc.

- It is prepared by mixing ordinary or rapid hardening cement and some percentage of some metal stearate ( Ca, Al etc).

- It is resistant to water and oil penetration.

- It is also resistant to acids, alkaline and salt discharged by industrial water.

- It is used for water retaining structure like tanks, reservoir, retaining walls, pool, dam etc

- Black chocolate color cement produced by fusing bauxite and limestone in correct proportion, at high temperature.

- Resists attack of chemicals, Sulphates, seawater, frost action and also fire. Useful in chemical plants and furnaces.

- Ultimate strength is much higher than OPC.

- Initial setting time is 2 hours, followed soon by final setting.

- Most of the heat is emitted in first 10 hrs. Good for freezing temperatures in cold regions (below 18°C).

- Develops strength rapidly, useful during wartime emergency.

- Unsuitable for mass concrete as it emits large heat on setting

10. Portland Slag Cement

- Produced by mixing Portland cement clinker, gypsum and granulated blast furnace slag.

- Cheaper than OPC, blackish grey in color.

- Lesser heat of hydration. Initial setting in 1 hr and final setting 10 hrs.

- Better resistance to soil agents, sulphates of alkali metals, alumina, iron and acidic waters.

- Suitable for marine works, mass concreting.

- Due to low early strength, not suitable for RCC.

- OPC with small quantity of air entraining materials (resins, oils, fats, fatty acids) ground together.

- Air is entrained in the form of tiny air bubbles during chemical reaction.

- Concrete is more plastic, more workable, more resistant to freezing.

- Strength of concrete reduces to some degree.

- Quantity of air entrained should not be more than 5% to prevent excess strength loss.

- OPC clinker and Pozzolana (Calcined Clay, Surkhi and Fly ash) ground together.

- Properties same as OPC.

- Produces less heat of hydration and offers great resistance to attacks of Sulphates and acidic waters.

- Used in marine works and mass concreting.

- Ultimate strength is more than OPC but setting timings are same as OPC.